Frameless Freeform Fabrication.

Welcome to the community.

Welcome to the community.

The tool head is held in place by lines. The lines are anchored either to a light frame, a crane or a hoist system or directly to the ceiling and floor of a room. Precision movements are controlled by adjusting the lengths of the lines with tightly synchronized motors.

The lightweight, compact format makes Hangprinter easy to transport and tidy away. The setup is quick since the anchors can be almost anywhere around the build volume. There are no ground preparation or alignment requirements. Quick-release anchors enable economical multi-usage of space. It frees up the area for other purposes as soon as the job is done.

A special motor mode lets the user set a constant pull in the lines with any desired force. It is used to tighten lines or wind them onto or out from the spools. When winding out, the pull is set to almost zero, allowing the operator to attach the quick-release anchors. When preparing for print, torque mode ensures the optimal initial line tightness. When tidying, torque mode can create a slight pull that makes the lines follow the hand movements of the operator.

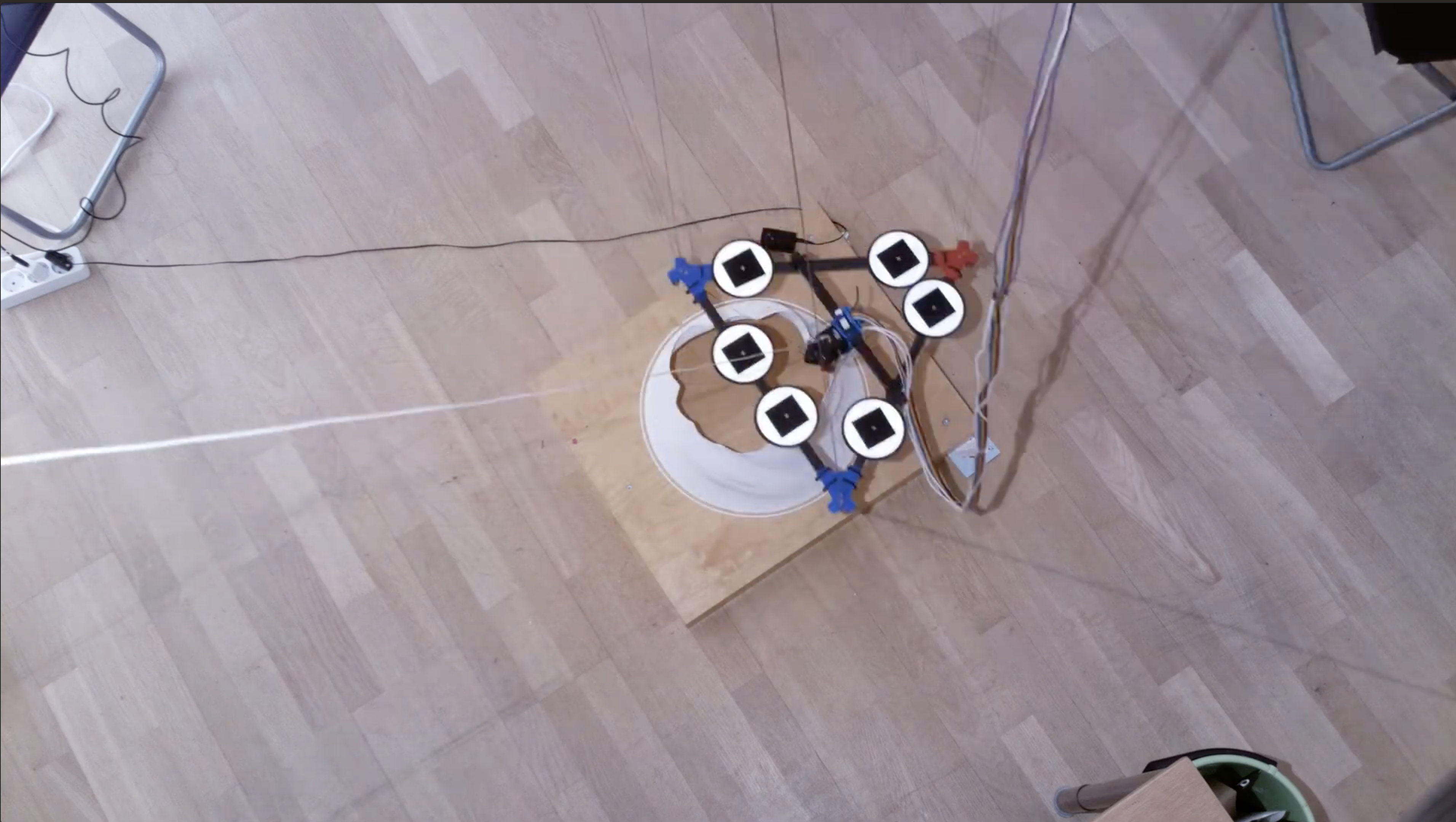

High precision is achieved by directly measuring and compensating in software. The most useful measurements currently come from our custom-built hp-mark computer vision system. It measures the tool's position and orientation by keeping track of a set of markers.

The auto-calibration process creates configuration values and checks config quality, ensuring that the software's expectations match measured physical reality. The routine is run only once and is divided into two steps:

Even our super stiff lines extend slightly due to the gravitational pull on the extruder. If left unaccounted for, this would cause sagging and precision loss. The flex compensation treats lines as if they were very tight springs. It uses these “springs” and some math to apply just the right amount of pull in every direction at all times.

Since some lines point downward during printing, there is a risk of collision with wider prints during operation. Our line collision detector performs checks to determine in advance whether such collisions will occur. The detector lets operators plan and avoid surprises.

Hangprinter works with any slicer, extruder, sensor, print bed, or other 3D printing peripheral. It runs a widely used firmware called ReprapFirmware. Many experienced 3D printer operators will feel at home instantly, software updates are frequent and the documentation is generally good.

Belts are intended to skip, and lines should slide out of their clamp if tightness gets too high. The enclosed cassettes prevent injuries and avoid spaghetti chaos by containing the lines onto the spools.